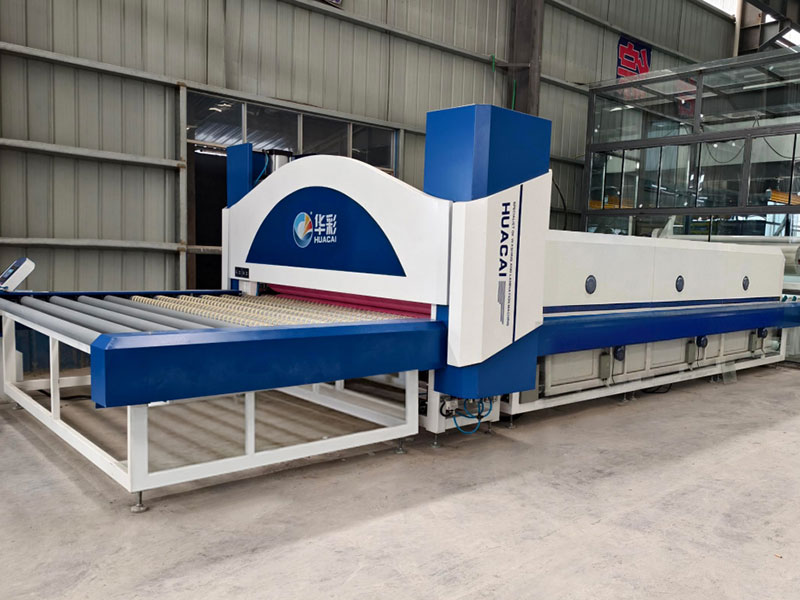

Heated Roller Press with Independent Temperature Controller

Huacai heated roller press with independent temperature controller is made up of the electrical cabinet and following operating zones: loading, pre-heating, pre-pressing, 1st heating, 2nd heating, roll pressing and unloading. The heated roller press is ideal for pre-pressing and bonding glasses with PVB interlayer.

After undergoing pre-heating, pre-pressing, heating and pressing, two or more layers of glasses and a PVB interlayer are preliminarily bonded together. The laminated glass roller press employs a series of superior high-temperature-resistant rubber rollers to expel any air pockets inside the glass and optimize bonding performance.

The machine body frame is made by quality steel profiles and sprayed with anti-corrosion and anti-rust paint to extend the working life.

Main transmission is designed with gear drive, variable frequency control and digital display of speed for precise and easy conveying speed control.

Transport rollers in heating section adopt bare roll shafts twined around with acrylic cords. Transport rollers in unloading section are vulcanized rubber rollers.

Temperature control system achieves sectional control of heating temperature, digital display and automatic constant temperature control. Heating elements are stainless steel heating pipes.

- Glass width (mm): 2500

- Glass thickness(mm): 6~80 (digital display)

- Min. glass size(mm): 400×400

- Power (KW): 102.1

- Conveying speed(m/min): 0.5~2.5

- Air pressure (MPa): 0.6~0.8

- Overall Dimension(mm): 9580×3500×1700