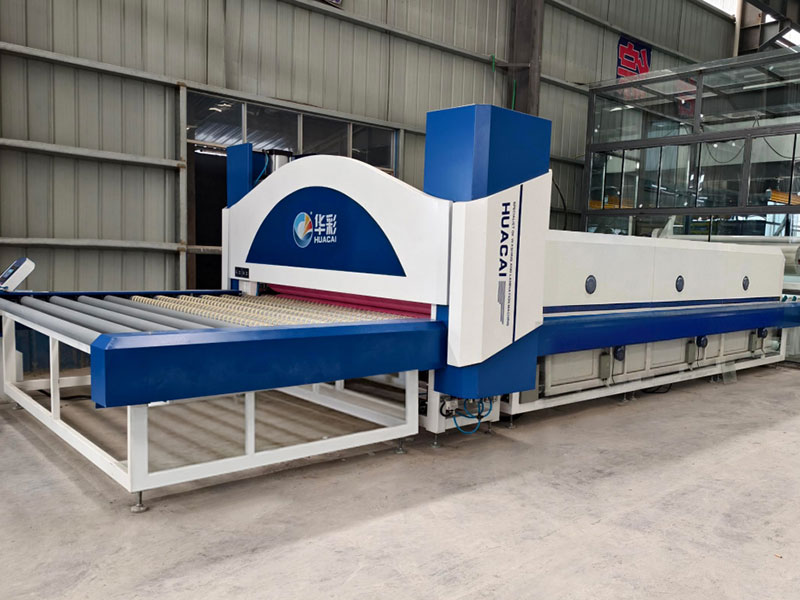

Curved and Flat Laminated Glass Roller Press

The curved and flat laminated glass roller press can manufacture flat or curved laminated glasses, widely used for the preliminary pressing of architectural, automotive, furniture and home appliance glass, low-E glass and bullet-resistant glass.

The curved and flat laminated glass roller press is able to replace the pre-pressing and heated pressing mechanism of the insulating glass production line. The glass roller press features superior rubber rollers which are against high-temperature and aging, stepless speed regulation drive mechanism, adjustable temperature control system, large-diameter cylinders supplying pressure for rubber rollers. According to the thickness and size of glass, air pressure can be regulated from 0 to 0.8MPa and the gap between rollers can be adjusted The curved and flat laminated glass roller press is comprised of the electrical cabinet and loading, pre-heating, pre-pressing, 1st heating, 2nd heating, 3rd heating, glass curving, roll pressing and unloading section. Lifting rollers for curved glasses are equipped in the curving section and unloading section.

The heating system features sectional control of heating temperature, precision digital temperature display and automatic constant temperature control. Quartz heating tubes are employed as heating elements, enhancing the heating efficiency and reducing energy consumption.

- Glass width (mm): 2500

- Glass thickness(mm): 6-40 (digital display)

- Min. glass size(mm): 400×400

- Power (KW): 118.2

- Conveying speed(m/min): 0.5-3

- Air pressure (MPa): 0.6~0.8

- Arch height: 300

- Overall Dimension(mm): 10380×3500×2500